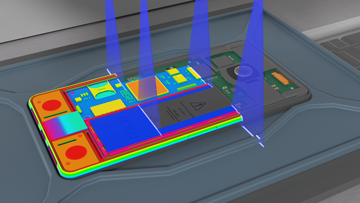

Do you have a need for product validation at high speed AND high precision? The most challenging factory floor measurement or inspection applications are routinely conquered with the the Gocator 2300 3D smart machine vision family of sensors.

Do you have a need for product validation at high speed AND high precision? The most challenging factory floor measurement or inspection applications are routinely conquered with the the Gocator 2300 3D smart machine vision family of sensors.

|

GOCATOR 2300 SERIES MODELS |

2320 |

2330 |

2340 |

2350 |

2370 |

2375 |

2380 |

|

Data Points / Profile |

1280 |

1280 |

1280 |

1280 |

1280 |

1280 |

1280 |

|

Linearity Z (+/- % of MR) |

0.01 |

0.01 |

0.01 |

0.01 |

0.04 |

0.03 |

0.04 |

|

Resolution Z (mm) |

0.0018 - 0.0030 |

0.006 - 0.014 |

0.013 - 0.037 |

0.019 - 0.060 |

0.055 - 0.200 |

0.175 - 0.925 |

0.092 - 0.488 |

|

Resolution X (mm) (Profile Data Interval) |

0.014 - 0.021 |

0.044 - 0.075 |

0.095 - 0.170 |

0.150 - 0.300 |

0.275 - 0.550 |

0.255 - 0.790 |

0.375 - 1.100 |

|

Repeatability Z (µm) |

0.4 |

0.8 |

1.2 |

2 |

8 |

12 |

12 |

|

Clearance Distance (CD) (mm) |

40 |

90 |

190 |

300 |

400 |

650 |

350 |

|

Measurement Range (mm) |

25 |

80 |

210 |

400 |

500 |

1350 |

800 |

|

Field of View (FOV) (mm) |

18 - 26 |

47 - 85 |

96 - 194 |

158 - 365 |

308 - 687 |

324 - 1010 |

390 - 1260 |

|

Laser Classes |

2, 3R |

2, 3R, 3B |

2, 3R, 3B |

2, 3R, 3B |

2, 3R |

2, 3R |

2, 3R |

|

Dimensions (mm) |

Side Mount 35x120x149.5

1.378x4.7x5.9

|

Top Mount 49x75x142

1.92x2.95x5.59

|

Top Mount 49x75x197

1.9x2.95x7.76

|

Top Mount 49x75x272

1.9x2.95x10.71

|

Top Mount 49x75x272

1.9x2.95x10.71

|

Top Mount 49x75x272

1.9x2.95x10.71

|

Top Mount 49x75x272

1.9x2.95x10.71

|

|

Weight (kg) |

0.8 |

0.74 |

0.94 |

1.3 |

1.3 |

1.3 |

1.3 |

|

ALL 2300 SERIES MODELS |

|

|

Scan Rate |

Approximately 170 Hz to 5000 Hz |

|

Interface |

Gigabit Ethernet |

|

Inputs |

Differential Encoder, Laser Safety Enable, Trigger |

|

Outputs |

2x Digital output, RS-485 Serial (115 kBaud), 1x Analog Output (4 - 20 mA) |

|

Input Voltage (Power) |

+24 to +48 VDC (13 Watts); Ripple +/- 10% |

|

Housing |

Gasketed aluminum enclosure, IP67 |

|

Operating Temperature |

0 to 50°C |

|

Storage Temperature |

-30 to 70°C |

|

Vibration Resistance |

10 to 55 Hz, 1.5 mm double amplitude in X, Y, and Z directions, 2 hours per direction |

|

Shock Resistance |

15 g, half sine wave, 11 ms, positive and negative for X, Y, and Z directions |

|

Scanning Software |

Browser-based GUI and open source SDK for configuration and real-time 3D visualization. Open source SDK, native driv- ers, and industrial protocols for integration with user applications, third-party image processing applications, and PLCs. |