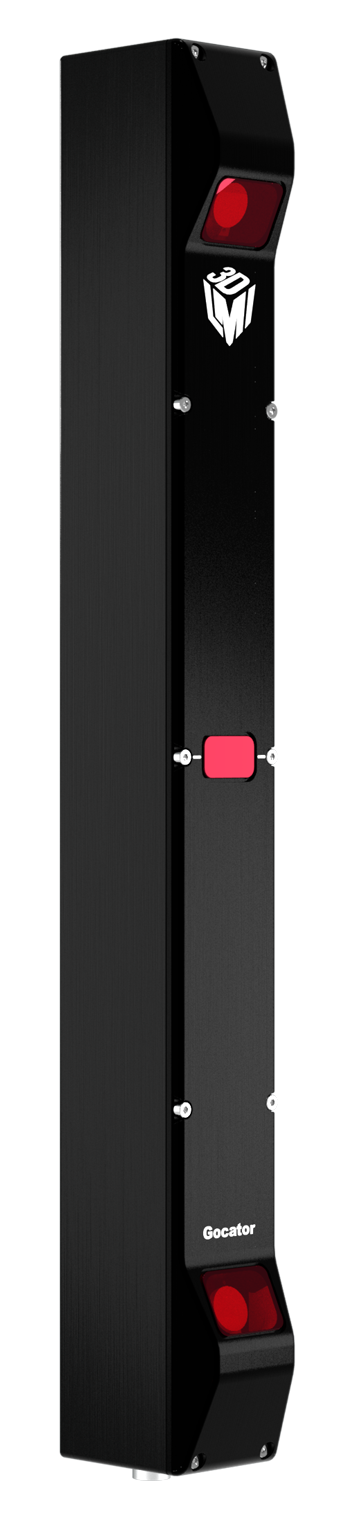

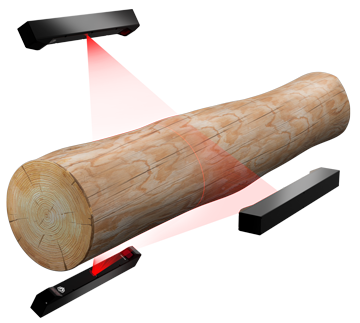

The Gocator 2880 3D industrial laser scanner will thrive in the demanding industrial conditions of your factory floor. All of the Gocator models, including the dual camera G2880, use a simple and flexible design which enables factories to reduce operational costs while they maximize profitability through

significant improvements in product validation.

The Gocator 2880 3D industrial laser scanner will thrive in the demanding industrial conditions of your factory floor. All of the Gocator models, including the dual camera G2880, use a simple and flexible design which enables factories to reduce operational costs while they maximize profitability through

significant improvements in product validation.|

GOCATOR 2880 |

|

|

Scan Rate |

380-2500 Hz |

|

Field of View (FOV) |

390 mm - 1260 mm |

|

Points per Profile |

1280 |

|

Resolution (X) |

0.375 mm - 1.100 mm |

|

Resolution (Z) |

0.092 mm - 0.488 mm |

|

Linearity (Z) |

0.04% of MR |

|

Clearance Distance (CD) |

350 mm |

|

Measurement Range (MR) |

800 mm |

|

Laser Class |

Visible 3B (<500 mW) |

|

Interface |

Gigabit Ethernet |

|

Inputs |

Differential Encoder Input, Laser Safety Enable, Trigger |

|

Outputs |

2x Digital output, 1x RS-485 Serial, 1x Analog Output (4 - 20 mA) |

|

Input Voltage (Power) |

+24 to +48 VDC (13 Watts); Ripple +/ 10% |

|

Laser Profiler Dimensions |

49 mm x 75 mm x 498 mm |

|

Weight |

2.56 kg |

|

Housing |

Gasketed aluminum enclosure, IP67 |

|

Operating Temperature |

0°C to +50°C |

|

Storage Temperature |

-30°C to +70°C |

|

Vibration Resistance |

10 to 55 Hz, 1.5 mm double amplitude in X, Y and Z directions, 2 hours per direction |

|

Shock Resistance |

15 g, half sine wave, 11 ms, positive and negative in X, Y and Z directions |