Pressure should be used to deliver a high-velocity stream

of media in blast cabinets when the hardness of the

substrate material can handle the higher pressures and the

media used is low-cost. All other things being equal,

inexpensive media used on hard surfaces by a high value

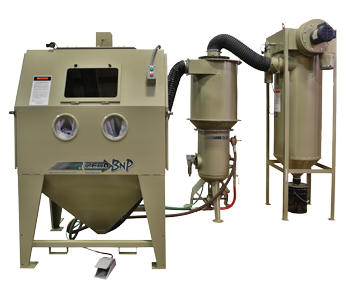

operator favors the selection of a direct pressure blast

cabinet.

Cleaning operations can routinely be completed in a third

or a quarter the time required when using suction

cabinet. This is particularly true for cleaning thick

layers of paint, scale, rust or corrosion.

Additionally, when a metallic media is required to prepare

the required surface finish, a direct-pressure blast

cabinet may be the optimal choice.

Some of the trade-offs for using pressure rather than

suction cabinets may be, a higher purchase price as

compared to an equivalent suction-blast cabinet, a more

rapid wear rate of all the wear-components in the system,

little opportunity to recover media after its first use,

and higher CFM demands on the system air compressor.

Always wear appropriate personal protection equipment when

operating machinery of any kind.