SODA BLAST

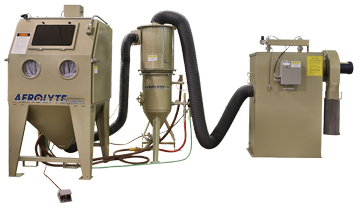

Aerolyte

Systems pioneered the use of lightweight media - plastic,

wheat starch, and baking soda - to dry strip coatings from

surfaces that might be damaged by conventional

abrasives. Applications include depainting aircraft,

automobiles and trucks, and appliances prior to inspecting,

repairing, and recoating. Aerolyte equipment ranges

from small portable blast machines, to elaborate

closed-circuit blast systems, to full-aircraft stripping

facilities.

DRY STRIPPING

Eliminate chemical stripping and the hazards it poses to

you, your employees, and the environment. Aerolyte pioneered

dry stripping, a process that removes coatings from delicate

substrates by blasting with lightweight media - plastic,

wheat starch, and baking soda.

Aerolyte Systems has continuously evolved dry stripping

technology and techniques. From portable pressure vessels to

closed-circuit stripping heads to hangar-sized facilities for

stripping aircraft, Aerolyte offers a broad range of standard

and custom-engineered equipment.

Dry stripping with lightweight media removes coatings without

pitting or warping the underlying surface. Dry

stripping saves time and money by eliminating the costs to

purchase, handle, and dispose of caustic chemicals.

To learn which media will most economically produce the

optimal surface finish, please click below to request a call

from one of our media specialists, and to arrange for

a

no

charge MEDIA SAMPLE TEST of your needs.

HTE Abrasive Blast Solutions is your resource for all your

Aerolyte needs if you are in

Kansas, Missouri, or

Illinois.

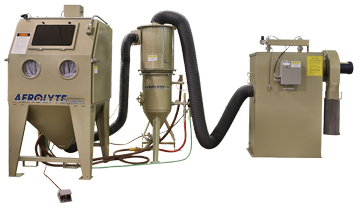

Aerolyte

Systems pioneered the use of lightweight media - plastic,

wheat starch, and baking soda - to dry strip coatings from

surfaces that might be damaged by conventional

abrasives. Applications include depainting aircraft,

automobiles and trucks, and appliances prior to inspecting,

repairing, and recoating. Aerolyte equipment ranges

from small portable blast machines, to elaborate

closed-circuit blast systems, to full-aircraft stripping

facilities.

Aerolyte

Systems pioneered the use of lightweight media - plastic,

wheat starch, and baking soda - to dry strip coatings from

surfaces that might be damaged by conventional

abrasives. Applications include depainting aircraft,

automobiles and trucks, and appliances prior to inspecting,

repairing, and recoating. Aerolyte equipment ranges

from small portable blast machines, to elaborate

closed-circuit blast systems, to full-aircraft stripping

facilities.