From medical components to automotive parts to electronics, many manufactured products must carry permanent identification marks for compliance, tracing, tracking or branding purposes, making industrial laser marking systems critical across many sectors. Superior to traditional labels or ink-based marking technologies, laser marks won’t wear, chip or fade and can produce identifiers that increase traceability in a more efficient and cost-effective way.

This blog will discuss the benefits of advanced laser marking systems, as well as the materials and applications where they will provide the greatest advantages.

What is Laser Marking?

Many manufacturers must create a permanent mark, such as 2D barcodes, QR codes, serial numbers or logos on the items they produce. This type of permanent part marking method may be required for quality control and standards, product liability, controlled recalls or customer requirements. But, whatever the reason, marking raw materials, semi-finished workpieces or final product during the manufacturing process must be done in an efficient and cost-effective way.

Traditionally marking was done using direct printing or labeling technologies, but marks created by these solutions do not always hold up over the lifetime of the object. More recently, laser marking has been the favored approach.

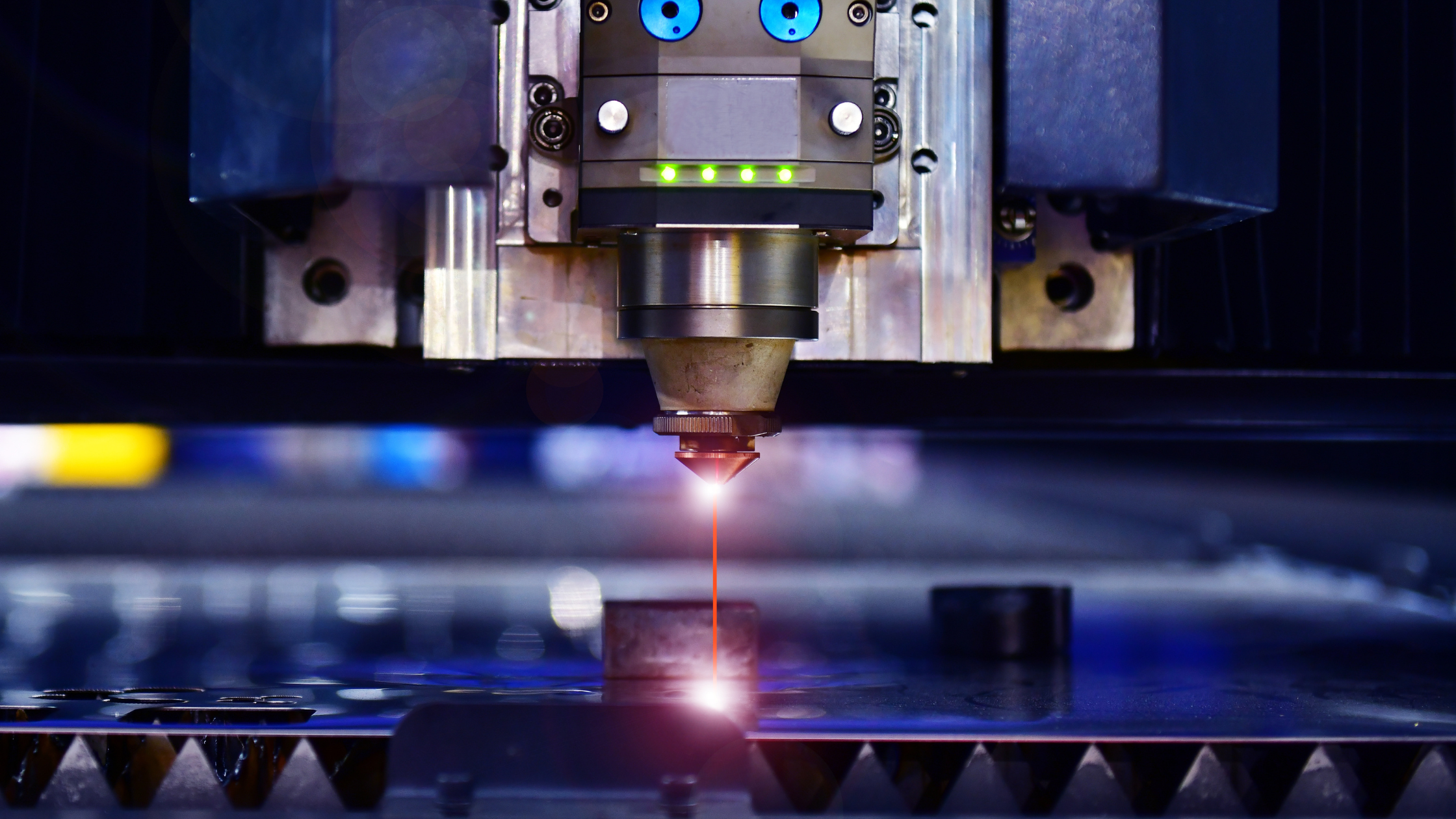

Laser marking uses a focused beam of light to permanently mark a surface and may be done by different types of lasers, including fiber lasers, CO2 lasers, pulsed lasers and continuous lasers. The beams of light generated by laser markers contain high levels of energy so that when a laser beam hits the intended surface, that energy is transferred in the form of heat and creates a permanent laser mark directly onto the surface.

Using advanced technology, laser marks are designed using software and then transferred to the laser marking system where software programming controls the movement, power and timing required to laser mark the component or object. Laser marking systems can be applied to a variety of surfaces and materials, including aluminum, stainless steel, plastics and rubber and laser marking systems can perform annealing, engraving, ablation or basic surface marking.

Applications for Laser Marking Systems

Laser marking is used throughout the industrial sector, but some common applications include:

| Medical devices | Because medical devices, such as surgical and diagnostic tools and implants, are used in medical care applications, they are strictly regulated and must be traceable. Identification marks must withstand sterilization, exposure to chemicals and frequent handling and remain legible throughout the lifetime of the device. Often these devices are made of titanium, stainless steel and advanced polymers. Laser marking meets all the criteria for medical device marking. |

| Electronics | Semiconductors, circuit boards, microchips and other electronic components typically carry codes, barcodes and/or logos or branding. When marking these sensitive devices, the mark must provide contrast and detail, but the method cannot damage or interfere with the fragile materials. Additionally, generated marks must withstand temperature variations, vibration and wear and tear of products such as cellphones, tablets and computers. Laser marking is ideal here because its non-contact marking method will cause no surface or material harm, but will provide a lasting laser mark. |

| Automotive and aerospace | These industries require traceability on parts and components for safety, warranty, recall, inspection and quality purposes, but generated marks must survive fluctuating temperature extremes, corrosion and high levels of vibration. Materials common to this industry include stainless steel, aluminum and titanium. Laser marking is suitable for these applications and materials. |

| Branding and logos | In general manufacturing and consumer goods, it is a common practice to apply logos and branding directly to products. Laser marking can be used to create high-contrast, high-resolution laser marks that do not wear off no matter how much a product is handled. |

| Packaging | Laser marking is replacing printed labels in many packaging applications where it may be used to apply permanent codes that will not smear or peel to cartons, bottles and blister packs. |

5 Advantages of Laser Marking Systems

Laser marking systems provide the following 5 benefits:

- Efficient: Laser marking is faster than other methods of permanent marking, so it provides greater throughput in shorter cycle times, making it a very efficient method of permanent marking.

- No contact: Because laser marking is a non-contact method, there is no mechanical interaction with the parts, which eliminates the need for clamping or fixturing, increasing efficiency. And, because laser marks can be generated without contact, it provides identification without damaging sensitive surfaces.

- Flexibile: Because laser marking systems can be programmed to create different effects, such as engraving or texturing, it is a flexible and agile method of marking components and workpieces.

- Sustainable: Laser marking does not require consumables, inks or solvents and does not produce waste, making it a sustainable marking method.

- Cost effective: Although laser marking systems have a higher initial investment cost, they offer a lower cost of ownership because there are no consumables. Additionally, laser marking systems are programmed for repeatability and consistency so there is no waste or rework. And, laser marks will not degrade over time. For these reasons, laser marking is a very cost-effective marking method.

Exploring a Next-Generation Laser Marking System

Based on fiber laser technology and developed to achieve high reliability in challenging manufacturing environments, Datalogic’s AREX400 is a next-generation series of high-performance laser markers.

These Datalogic scanners incorporate the new “LASERGREENSPOT” technology, which is a programmable visual indicator for immediate and effective visible process feedback directly on the marking area. And, the embedded controller offers an all-inclusive design, so no external PC or hardware is needed. Communication protocols, including TCP/IP, EtherNet IP and Profibus, are embedded.

AREX400 laser markers can be used for laser marking metal and plastic surfaces. It can be used as a laser marking machine for metal materials including, stainless steels, high-grade steel, steel, carbon steel, copper, iron, ferrous metals, magnesium, aluminum, brass, gold, silver, platinum, and titanium. The Datalogic scanner AREX400 Series can be used for advanced plastic marking of polyamide, polyoxymethylene, polypropylene, polyethylene and many other plastics.

On these and other surfaces, the AREX400 Series can create high readability text and codes on metals and color-enhanced thermoplastics, as well as quick and clear black laser annealing without cracks or thermal damage and high-speed deep engraving for traceability applications. The laser marking system can also be used for personalization and branding with high-resolution logos, graphics, texturizing or other aesthetic permanent markings.

Contact HTE to learn more about the AREX400 laser marking system and how it can bring efficiency and cost effectiveness to your traceability and brand marking applications today.