From small shops to large manufacturers, nearly every industry relies on compressed air to operate pneumatic tools and machinery. But contaminants and moisture contained in treated air can damage equipment, degrade the quality of finished products and increase energy consumption. Fortunately, the addition of filters and compressed air dryers ensures reliable equipment performance, improves product quality and maximizes system efficiency, reducing operating costs.

Why You Need Compressed Air Filters and Dryers

The atmospheric air drawn into your compressor contains water vapors along with dirt, dust and other airborne particulates. If not properly removed by compressed air filters and a dryer, it can cause a host of issues.

Particulates reduce efficiency and quality

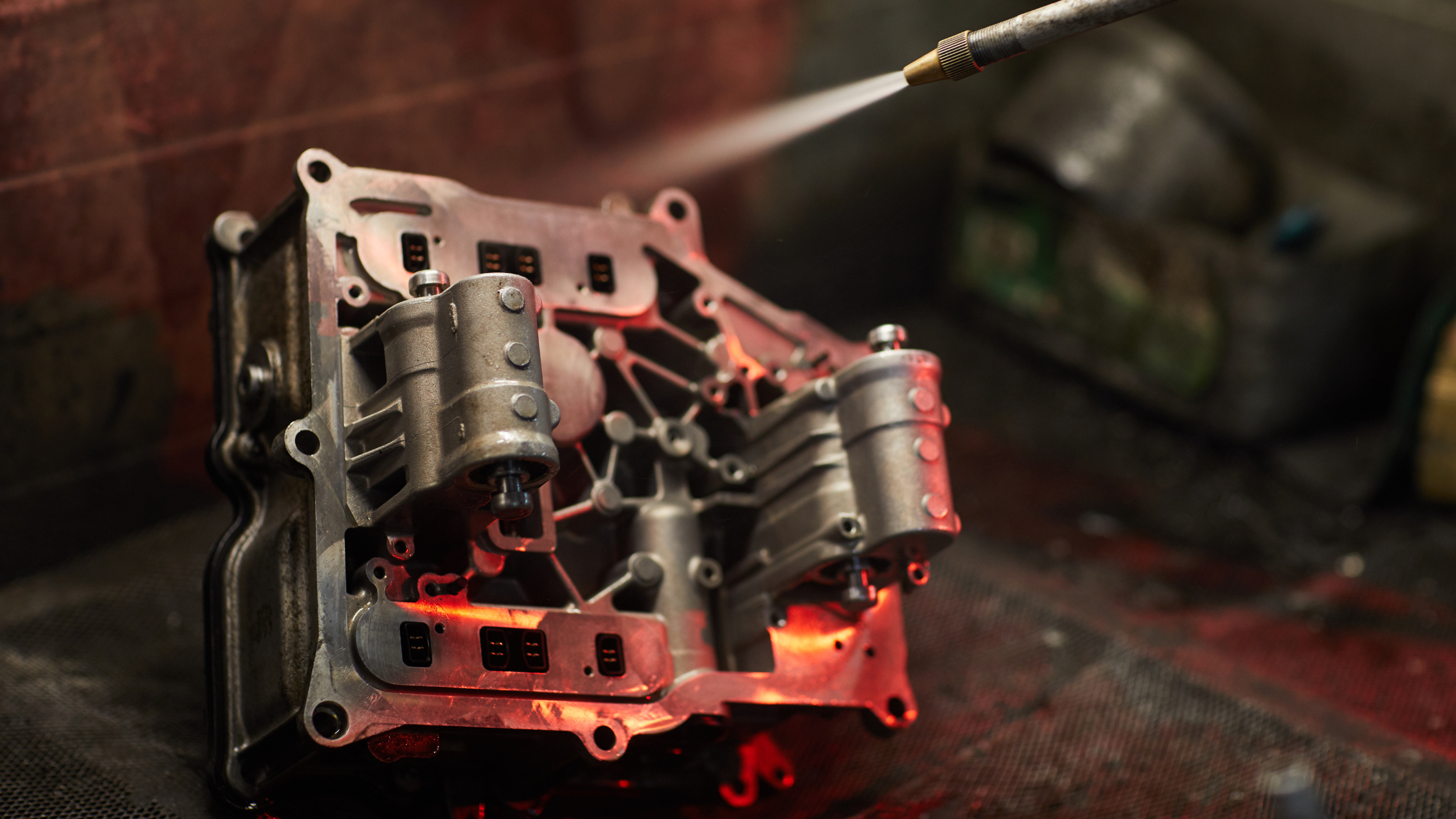

Dust, dirt and other particulates are drawn in with the intake air. Rust, caused by moisture-induced corrosion, and oil vapors, introduced during normal compressor operation, are also common contaminants. Introduction of these contaminants into the air compression system causes blockages and pressure drops, which negatively impact energy efficiency and equipment performance. Further, contaminants caught in the air delivery system may pass into pneumatic tools and machinery or finished products, damaging tools and product quality.

Particulate in the air compression system can lead to:

- Oil vapors, corrosion and contaminants such as dirt, dust and bacteria can be passed through the air delivery system and ruin finished products.

- Non-compliance with industry standards for clean, dry compressed air in sensitive industries like food, pharmaceutical, medical device and electronics manufacturing.

- Pressure drops that force the system to work harder, causing wear and tear on the compressor, increasing maintenance requirements and reducing asset lifetime.

- Pressure drops that increase energy consumption and electric bills.

- Pressure drops that reduce the effectiveness of connected pneumatic equipment.

- Damage to pneumatic tools and equipment that cause maintenance issues and poor equipment performance.

Water vapors introduce moisture

In operation, air compressors reduce the temperature of the intake air and apply high pressure to compress the air into a smaller volume. As the air is compressed and its temperature drops, it cannot hold the same volume of water vapor. The excess moisture turns into liquid condensation that can enter the air compression system, causing corrosion and contamination that reduce energy efficiency, tool reliability and finished product quality.

Moisture in the system can lead to:

- Corrosion and rust within the air compression system that damages system components and reduces energy efficiency.

- Corrosion and rust can be introduced into pneumatic equipment and instrumentation, damaging machinery and causing false instrument readings.

- Contamination of finished products.

- Poor adherence of paints and coatings applied with pneumatic spray machines.

- Non-compliance with industry standards for clean, dry compressed air in regulated industries like food, pharmaceutical, medical device and electronics manufacturing.

Achieving Compressed Dry Air

Moisture can be removed from treated air via a compressed air dryer system. Although most air compressors offer integrated drying systems, such as aftercoolers, they don’t effectively remove all the moisture, especially in humid environments or in sensitive industries with strict air quality standards. The addition of a compressed air dryer is the best way to achieve high-quality dry air and avoid maintenance and product quality headaches.

Types of Compressed Air Dryers

There are three commonly used types, including:

- Refrigerated Air Dryers: Refrigerated air dryers are connected to the air compressor and cool the air using a heat exchanger, a refrigerant circuit and a compressor. Incoming air is chilled, causing the moisture to condense and collect in a separator until it is drained, then the air is reheated. Refrigerated air dryers are energy efficient and suitable for locations where the ambient temperature is lower than 100°F. They are popular general manufacturing and auto shops.

- Desiccant Dryers: Desiccant dryers have a tower filled with absorbent material, called a desiccant, that attracts and removes water from the air. Once the specified moisture content is achieved, the air is moved out of the dryer and is ready for use. Desiccant dryers are ideal in low-temperature climates and applications that demand the cleanest, driest air, such as medical device, pharmaceutical and electronics production.

- Membrane Dryers: Using selective permeation and a multiple-stage filtration system, membrane dryers effectively separate moisture from compressed air. Following the initial separation, the membrane removes any remaining water vapor, resulting in clean, ultra-dry treated air. They require little maintenance, but must be inspected often to ensure that there is no fouling or clogging in the membrane.

How to select an air dryer for compressed air

When specifying a compressed air dryer, it’s critical to consider the application requirements, especially if you are in an industry that regulates compressed air quality, such as food and beverage, medical device, pharmaceutical and electronics manufacturing or if your application requires ultra-dry air for spray painting or coating. These applications may benefit from a desiccant or membrane dryer. Most other applications will likely find a refrigerated air dryer acceptable.

Noting the humidity level and temperature of your location is also essential as hot, humid air contains more moisture and may require a larger or more specialized compressed air dryer.

Ensure system drainage

Air compression systems contain drains where excess moisture and water content collect for removal. Drains should be emptied and inspected frequently to ensure they are in good working order. Drains that don’t open will result in moisture-induced corrosion and contamination in the system and drains that don’t close will reduce energy efficiency of the system.

Get Contaminant-Free Air with Compressed Air Filters

By collecting contaminants before they enter the system, compressed air filters are key to keeping your air compression system free of dirt, dust, moisture and oil vapors.

Types of compressed air filters

Several types of filters are available for air compression systems, but the three most common include:

| Coalescing or prefilters | These are used to remove oil and water droplets from compressed air. They capture contaminants and merge them into larger droplets that are drained from the system. |

| Particulate filters | Particulate filters are designed to remove fine, solid particulates like dirt, dust and rust from the system. |

| Carbon filters | These filters remove odors, vapors and mists from compressed air. |

The importance of compressed air filter maintenance

Clogged filters of any kind will cause blockages and pressure drops that reduce system efficiency, degrade pneumatic equipment performance and cause wear and tear on the compressor, its components and connected tools. All compressed air filters should be inspected, cleaned and replaced as part of a routine air compressor maintenance program to ensure energy efficiency and effective equipment operation.

Achieve High-Quality Air with Compressed Air Filters and Dryers

Don’t let dirty, moist air drive up your electric bills, mess with tool performance or ruin your finished products. Enlist the help of the experts at HTE to find the compressed air dryer and filters that best meet the needs of your application so you can be sure your compressor produces the cleanest, driest air possible.