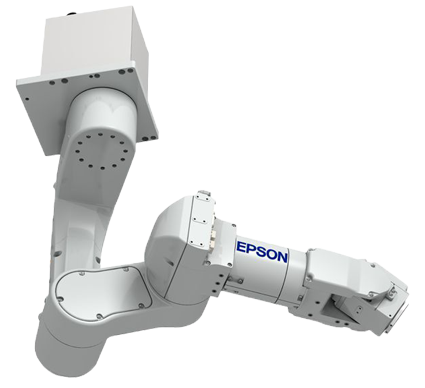

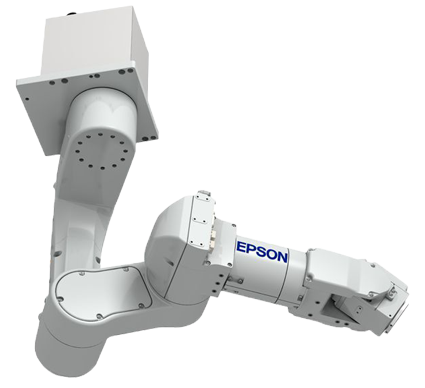

6 AXIS ROBOT

Mass

production shifted into high gear with the introduction of

the traditional industrial robotic arm during the last half

of last century. Industrial robots are complex machines that

are programmed to perform a series of complex and precise

tasks without continual direct human worker involvement. The

computer embedded within the robot can be reprogrammed to

perform different tasks, but such changes are expensive,

requiring the expertise of a highly educated robot programmer

or robotics engineer.

ARTICULATED ROBOT

Traditional robots are commonly implemented to perform

high volume, repetitive task that require precision and

endurance well beyond a human worker’s ability. The

industries where industrial robots are implemented include

manufacturing, automobile production, packaging, electronics,

pharmaceuticals, and transportation.

ROBOT

SAFETY

ROBOT

SAFETY

The most common tasks robots have been used for, are

those that are dangerous to humans, are too large, or too

small for humans, are in extreme environments, or are highly

repetitious. Adding to the dangerous environment, traditional

industrial robots are themselves dangerous to human workers

because of their power, speed, and inability to accommodate

changes in their working environment.

For worker safety, traditional industrial robots are always

accompanied by a complex series of safety rated sensors and

controllers designed to reliably stop all robot motion when a

person or object enters their working space. Physical

guarding and or light curtains may also be employed.

HTE Automation supplies industrial robots and engineering

services for their optimization to manufacturers in

Kansas, Missouri, and Illinois.

Mass

production shifted into high gear with the introduction of

the traditional industrial robotic arm during the last half

of last century. Industrial robots are complex machines that

are programmed to perform a series of complex and precise

tasks without continual direct human worker involvement. The

computer embedded within the robot can be reprogrammed to

perform different tasks, but such changes are expensive,

requiring the expertise of a highly educated robot programmer

or robotics engineer.

Mass

production shifted into high gear with the introduction of

the traditional industrial robotic arm during the last half

of last century. Industrial robots are complex machines that

are programmed to perform a series of complex and precise

tasks without continual direct human worker involvement. The

computer embedded within the robot can be reprogrammed to

perform different tasks, but such changes are expensive,

requiring the expertise of a highly educated robot programmer

or robotics engineer. ROBOT

SAFETY

ROBOT

SAFETY