PREVENTATIVE MAINTENANCE

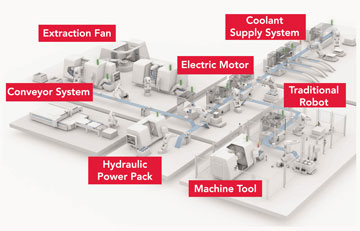

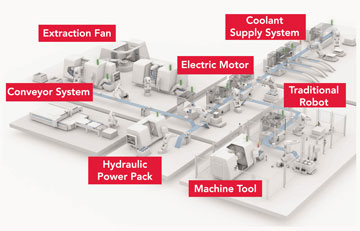

Which are your most critical production processes or machines? Do you ever worried about them, whether they are functioning optimally or approaching a failure condition?

The promise of the Industrial Internet of Things or IIoT, is that you can have data at your fingertips even when you travel away from your production plant, or when your plant is remote, anywhere on the planet in fact.

PROCESS MONITORING

But a full blown IIoT project seems technically overwhelming and implementation expensive, just for monitoring a few machines or processes.

With the simplicity of Balluff’s Condition Monitoring Toolkit (CMTK), you can forget the fancy words, complex technologies, and the big budget. As the trusted global leader in process sensing, and with tens of thousands of sensor sku’s to choose from, Balluff already knows how to, and can, measure your process parameters.

REMOTE MONITORING

Plus, with their rock-solid IO-Link communication device reliability, you will be able to see the real time performance of those critical processes no matter where you are in the world.

Balluff’s CMTK system delivers peace of mind in an easily implemented and rapid ROI solution. Know with confidence that “the usual suspects” are running well and are not just about to cost you unplanned downtime.

The highly flexible CMTK system allows you to select up to any four Balluff IO-Link sensors, each matching your sensing needs, which are then connected to a base unit that is equipped with integrated software.

With this simple system you can detect conditions that may lead to future problems, and easily preschedule maintenance routines when they will be least disruptive.

REMOTE IOT MONITORING

The software automatically displays the incoming data in a dashboard format that matches the sensor types you select, making setup quick and easy.

Your system will make use for the end devices common to your plant, delivering convenient access to this critical information by your team.

Balluff’s base-unit is a small computer delivered with preinstalled (no fee-based license) CMTK software which lets you configure limit, or min/max values, analyze trends, and trace error chains. The base-unit also connects to other networks and systems if you so choose.

Mounting of the base-unit occurs central to the placement of sensors in the machine or process and does not require interfacing with the machine’s controls, and the system is also independent of a cloud or internet connection.

Balluff and HTE Automation work with manufacturers in

Kansas, Missouri, and Illinois, to accelerate, optimize, and secure production process by applying technology-based solutions in their industry. Call us at 800-444-4831 and get some peace-of-mind installed at your plant today.

Which are your most critical production processes or machines? Do you ever worried about them, whether they are functioning optimally or approaching a failure condition?

Which are your most critical production processes or machines? Do you ever worried about them, whether they are functioning optimally or approaching a failure condition?  Plus, with their rock-solid IO-Link communication device reliability, you will be able to see the real time performance of those critical processes no matter where you are in the world.

Plus, with their rock-solid IO-Link communication device reliability, you will be able to see the real time performance of those critical processes no matter where you are in the world.