Although most manufacturing processes require high-quality welding, the industry is experiencing a shortage of skilled welders. For this reason, welding automation equipment has evolved to include technologies that span from traditional stationary robotic welders to versatile welding cobots, so there is robotic welding equipment available to suit every need. However, the use of cobot welding cells is growing at a rapid pace because they are easy to deploy and flexible, making cobot welding an appropriate and cost-effective welding solution for businesses of any size.

This blog will explore the benefits of welding cobots, as well as the available types of robotic welding equipment.

The Benefits of Welding Cobots

There is a growing need for manufacturers of all sizes to maximize efficiency, boost productivity, minimize waste and cut costs while maintaining high quality, and automation provides a sensible and cost-effective solution, especially when it comes to welding. Automated welding machines can be successfully applied to small, medium and large businesses that are facing a shortage of skilled welders, have only a few welds in the process or require greater precision, speed and consistency in their welds.

As a matter of fact, cobot welding provides several distinct benefits, including:

Maximized Efficiency and Productivity: Because they do not require breaks or become fatigued, welding cobots can help maximize efficiency and productivity, ensuring that welding tasks are accomplished quickly, but also with high levels of accuracy and consistency. In addition, today’s cobot welding machines are easy to set up, reconfigure and reprogram to provide faster transitions between projects, significantly reducing the downtime associated with manual welding and retooling.

Higher Levels of Quality: Today’s cobot welding equipment provides exacting control over welding parameters including speed, distance and angle, enabling welds that meet specifications with consistency and precision. The high levels of accuracy and repeatability provided by robotic welding machines result in fewer defects, less wasted material, fewer labor hours and higher levels of product quality.

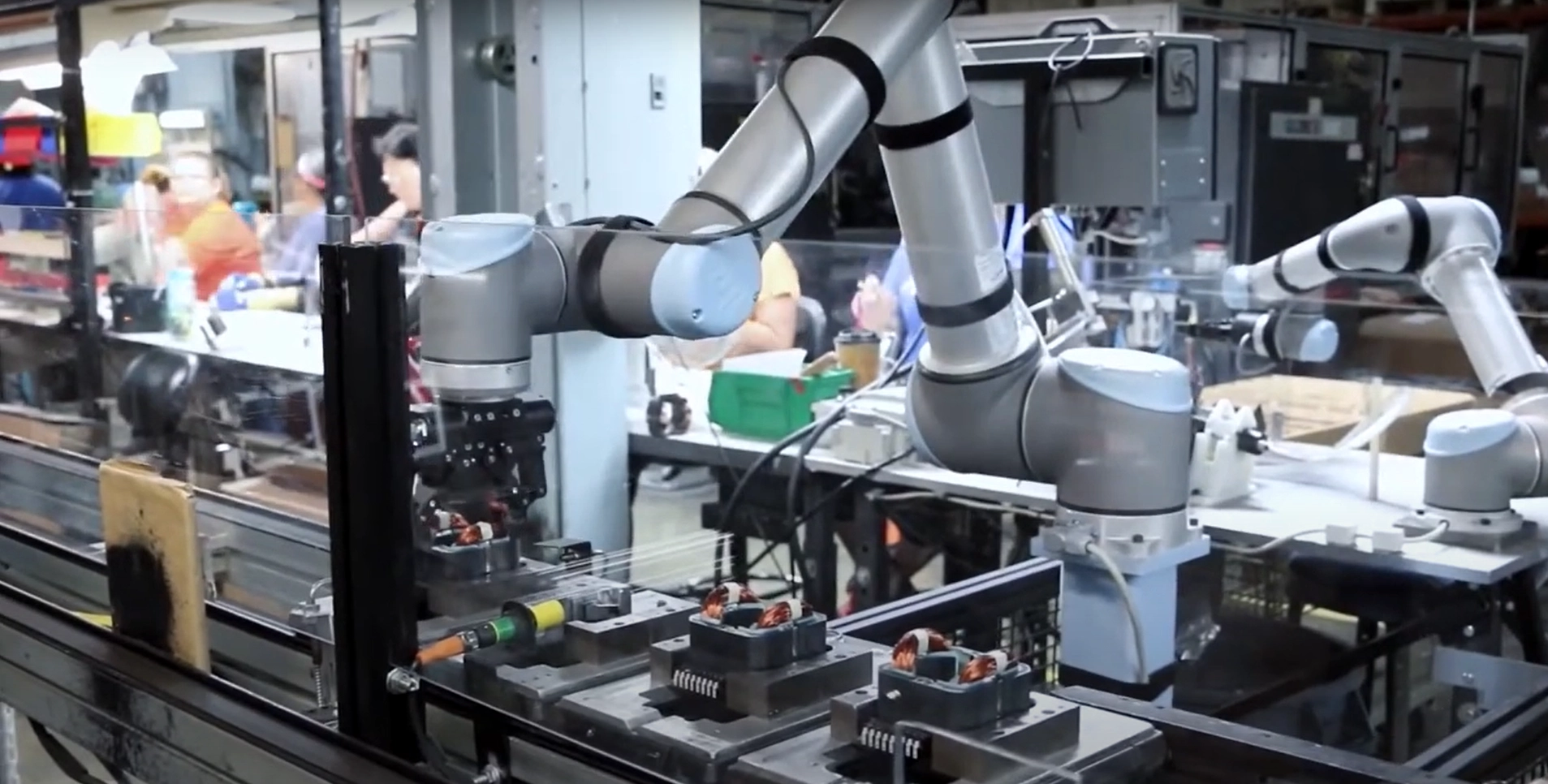

Greater Flexibility: Today’s welding cobots are easier to deploy than traditional industrial robotic welders as they do not require extensive setup or complex programming. Because they are easy to program, are highly adaptable to multiple welding types and are designed to be used near human workers, cobot welding may be used in a variety of locations and for a wide range of welding tasks, making them a more flexible and cost-effective alternative to manual welding and traditional stationary robotic welders.

Increased Safety: Welding is a hot and hazardous task, so using robotic welding machines to manage welds minimizes the risks to human welders. In addition, welding cobots, like all cobots, offer built-in safety features such as sensing if the robot has come into contact with an object or operator, thus halting motion and preventing serious injury. With the ease of programming, additional sensors can be integrated to further this and halt the robot before any collision is made.

What Types of Welding Can Robotic Welding Equipment Perform?

Because robotic welding equipment offers a host of benefits, many manufacturers are considering automating their welding, so welding automation is available to handle MIG, TIG, cutting, laser, spot and orbital welding tasks and many can be programmed to handle a range of welding types. However, MIG and TIG cobot welding are among the most widely used techniques.

So, when selecting a welding cobot, it’s important to understand the difference between MIG and TIG welding, as discussed below:

- MIG welding: MIG stands for “metal inert gas” welding, which is a process that combines two pieces of metal together with a consumable wire connected to an electrode current. The wire passes through the welding gun along with the gas, which protects the electrode from contaminants. MIG welding is often used because it is easier and more efficient than other types of welding, making it suitable for high-production rates. However, it is less precise than other welding techniques.

- TIG welding: TIG stands for “tungsten inert gas” welding, which is a process that uses non-consumable tungsten along with an inert gas to weld two pieces of metal together. The tungsten electrode provides the arc for the welding process. TIG welding creates precise, clean welds and is more accurate than MIG welding, so is often used where precision and clean welds are required.

With the difference between MIG and TIG welding explained, we can delve into when one type of robotic welding equipment would be more appropriate than the other, as follows:

MIG welding cobots provide precise control and maneuverability over highly sensitive MIG welds. They are economical when used in high-mix/low-volume applications. Complete MIG welding systems are usually equipped with a welding cobot, welding power supply, torch, welding cart, clamps and basic controls. MIG cobots are versatile and can be programmed to manage tack welding, weaving, linear welds, circular welds, stitch welding and patterns.

TIG welding cobot cells are a suitable choice when users seek greater control and stability for complex welds for thin metals. TIG welding cobots can be used for diverse robotic welding applications and can help offset labor costs and concerns about skilled labor shortages. TIG cobot cells can be set up for a variety of welds, including tack welding, weaving, linear welds, circular welds, stitch welding and patterns.

No matter what type of weld the robotic welding machine is to perform, the equipment is usually customized to the specifications of the application and likely includes a combination of the following components:

- The welding cobot

- The welding system, which includes the power supply, control interface, cabling, the housing and a cooling system

- A mobile welding cart, or cobot base, with clamping and fixturing components

- A weld end-effector, or welding torch, which is held at the end of the cobot arm

- Safety equipment, including curtains and arc shields

- The programming interface and control software for operators

- Other options may include a variety of torches, wire feeders, tooling to hold parts and rail systems for additional reach

As the shortage of skilled welders continues and manufacturers struggle to maintain high levels of quality and efficiency, welding automation can help maintain high levels of productivity, while providing precise and consistent welds in a safe way. To learn how robotic welding equipment can improve the accuracy and efficiency of your welds, please contact HTE Technologies, a Tavoron company, today.