Cleated and Specialty Conveyor Belts: A Guide for Manufacturers

By: Scott Wojciak

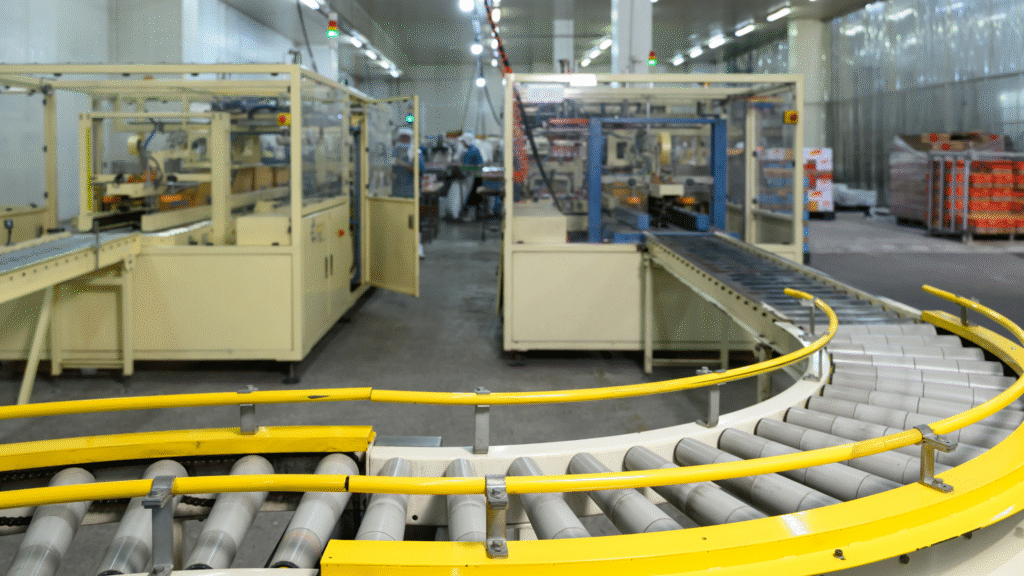

The right conveyor belt maximizes the efficiency and productivity of your manufacturing operation. But if your conveyor moves bulk, loose, lightweight or fragile materials and general-purpose conveyor belting is slowing down your process, specialty or cleated conveyor belts can increase productivity and throughput.

This guide to choosing a conveyor belt type for manufacturing will provide information on cleated conveyor belts and how they – and other types of specialty conveyor belts – can streamline your toughest material handling challenges.

What is a Cleated Conveyor Belt?

Cleated conveyors feature vertical cleats along the width of the conveyor belt to keep loose, fragile or oddly shaped materials secure as they move through a facility. Cleated belts transport bulk materials to minimize spillage and product loss, protect fragile items, ensure consistent spacing between objects or stage products for assembly.

Cleated conveyor belts may feature small cleats to keep objects in place, larger cleats for transporting loose materials, or custom-placed cleats to meet unique manufacturing requirements.

Applications for Cleated Conveyor Belts

Every manufacturer has different material handling needs, but cleated conveyor belting solves a variety of challenges. Common conveyor belt cleat applications include:

Food processing: Cleated conveyor belts transport loose ingredients or fragile food items to prevent spills and damage.

Packaging: Incline conveyor belt cleats are used to prevent slippage of products or boxes as they move up or down different levels in a facility via incline/decline conveyors.

Automotive manufacturing: Cleated conveyor belts transport car parts and components between manufacturing processes.

General manufacturing: Cleated belts transport bulk materials to prevent spillage, safely transport fragile materials or evenly space products for assembly.

Recycling: Incline conveyor belt cleats sort, separate and secure glass, paper and plastics in multi-level recycling operations.

Other Types of Specialty Conveyor Belts

Many manufacturers have unique products or processes, so there is likely a belt solution designed to handle your special requirements.

Here are few specialty conveyor belt types:

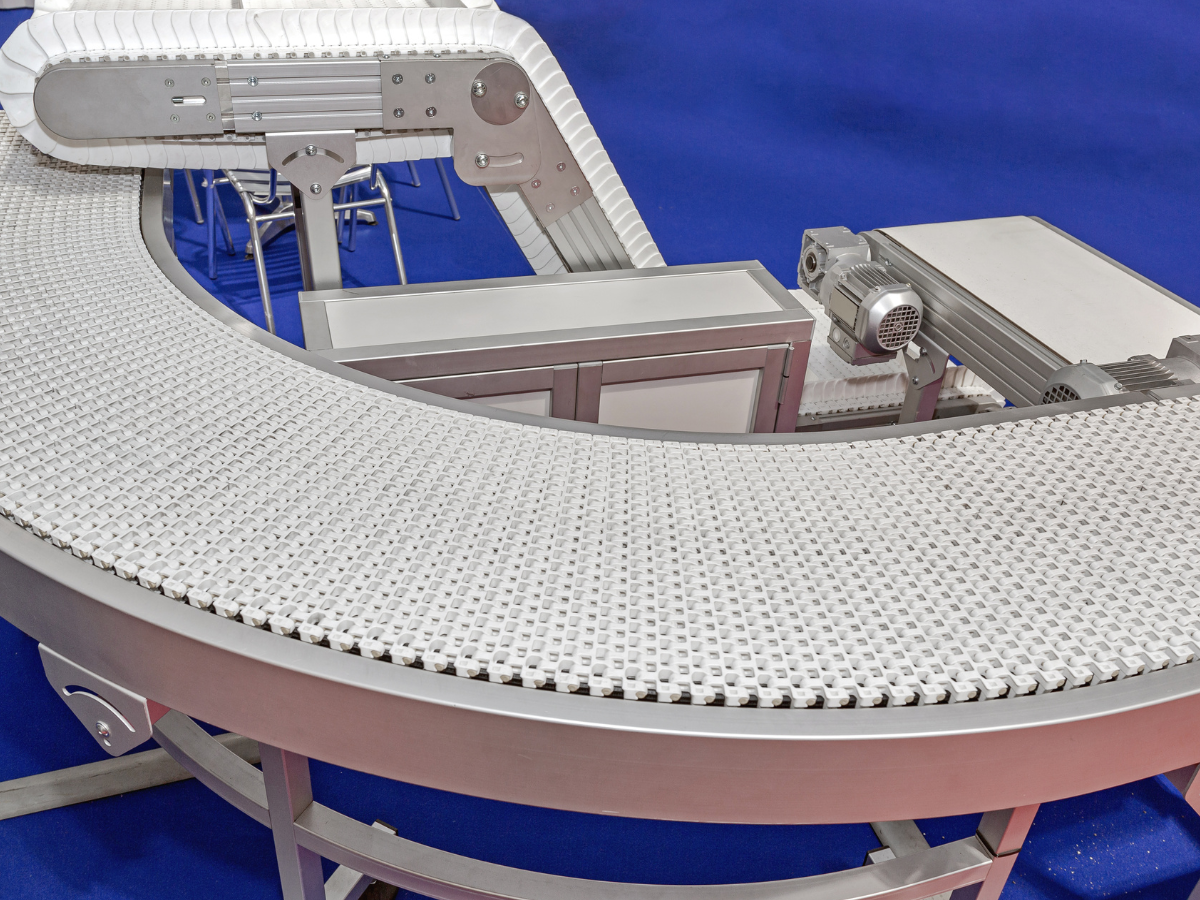

- Sanitary/washdown: In some applications, such as food and pharmaceutical processing, high-temperature, caustic washdown and sterilization procedures necessitate stainless steel belting to withstand harsh conditions.

- Incline/decline: Incline/decline conveyors, a solution for facilities that move products up and down levels, often include incline conveyor belt cleats to secure product during ascent and descent.

- Perforated: Perforations in belting increase the efficiency of some processes such as washing or drying.

- High grip: High-grip coatings can be added to belts to prevent product shifting, provide more accurate positioning or to prevent product loss/damage.

- Temperature resistant: Belts can be made from specialty materials like silicon to withstand extreme temperatures.

Cleated and Specialty Conveyor Belts Solve Challenges

Material handling is not a one-size-fits-all solution. Cleated and specialty conveyor belts solve a lot of challenges – and provide worthwhile advantages – in unique applications.

5 Big Advantages of Specialty Conveyor Belts

- Optimized Efficiency: The wrong conveyor belting causes slippage, damage and downtime. Using belting specially designed to safely and effectively move challenging products enhances performance and increases efficiency.

- Reduced Product Loss: When product will not stay on the conveyor, product loss costs add up fast. Cleats prevent materials from falling off or spilling, reducing costs.

- Increased Quality: When products fall off conveyors, they sustain damage. Cleated conveyor belts keep them in place, increasing quality and reducing scrap costs.

- Minimal downtime: Using the wrong belting – for example, general-purpose solutions in washdown applications – leads to belt breakage. Solutions like high-temperature or stainless steel belting designed to meet process needs minimize downtime and repair/replacement costs.

- Lower Costs: Using the right specialty conveyor belt solution for your application prevents product loss, bottlenecks, damaged products and belt breakage, lowering operational costs and boosting profits.

Choosing a Conveyor Belt Type for Manufacturing

When evaluating specialty conveyor belting, there are several key considerations.

Material Characteristics

Is the product fragile, round or oddly shaped? Is it lightweight or loose raw material? Will it shift on the conveyor? Can it move up or down inclines without support? Cleated conveyor belting solves these challenges.

Environment

If you use harsh or caustic chemicals, have strict cleaning regimes or your conveyor belting is exposed to extreme hot or cold temperatures, specialty conveyor belts will withstand the environment.

Speed and Load

Ensure any selected conveyor belting provides the necessary speed and supports the maximum load for top-notch performance.

HTE Can Help with Your Cleated and Specialty Conveyor Belt Needs

When you have challenging conveying needs, specialty or cleated conveyor belts can provide higher levels of productivity and reliability. When the automation experts at HTE help you find a conveyor belt solution that meets your unique requirements, materials will move smoothly, safely and efficiently through the manufacturing process. Contact us today to start working smarter.

See our primary conveyor line here.

-

Scott Wojciak, a seasoned executive with deep expertise in industrial automation and distribution, serves as Senior Vice President of Automation at Tavoron. He previously led the Fluid Power, Automation, and Engineered Solutions Division at Singer Industrial and held leadership roles at BW Rogers, including Vice President of Sales, Director of Sales, and Regional Business Unit Manager. Known for his results-driven approach and customer-focused leadership, Scott has spent his entire career advancing commercial strategy and operational performance across the automation sector. He began his career as a Sales Engineer and earned BW Rogers’ Salesman of the Year award early in his tenure.

View all posts